Understanding The Kicker's Fire-Refining Process

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit Best Website now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Understanding the Kicker's Fire-Refining Process: A Deep Dive into Gold Purification

The allure of gold, a precious metal prized for its beauty and value, has captivated humanity for millennia. But the gold found in nature rarely exists in its pure, 24-karat form. It’s often mixed with other metals, requiring a refining process to achieve its desired purity. One such method, particularly relevant in smaller-scale operations, is the kicker's fire-refining process. This article will delve into the intricacies of this technique, exploring its steps, safety precautions, and overall effectiveness.

<h3>What is Kicker's Fire Refining?</h3>

Kicker's fire refining, also known as cupellation or simply fire assaying (in a broader context), is a traditional method of refining gold and silver that uses heat and oxidation to separate precious metals from base metals. Unlike more sophisticated methods used in large-scale refineries, the kicker's method is relatively simple and accessible, making it suitable for smaller-scale operations or hobbyists. It relies on the differing melting points and oxidation properties of different metals.

The name "kicker" likely refers to the physical act of occasionally "kicking" the crucible during the process to ensure even heating and proper oxidation. This is a crucial aspect of maintaining control and avoiding uneven refining.

<h3>The Steps Involved in Kicker's Fire Refining:</h3>

The process typically involves the following steps:

-

Preparation: The gold-bearing material, which could be scrap gold, doré bars, or other alloys, is carefully weighed and prepared. This might involve crushing or melting the material down into a manageable form.

-

Melting and Oxidation: The material is then melted in a crucible, usually made of clay or a similar high-temperature material. A lead flux is often added. Lead acts as a collector for base metals, forming an alloy with them. As the mixture is heated, air is allowed to circulate, oxidizing the base metals (like copper, zinc, and iron) which are then absorbed into the porous cupel.

-

Cupellation: This is the core of the kicker's fire-refining process. The molten metal is poured into a cupel, a porous cup-shaped vessel typically made from bone ash. The heat and air flow cause the base metals to oxidize and be absorbed into the cupel, leaving behind the purified precious metals (gold and silver).

-

Separation (if necessary): If silver is present in significant quantities, parting is necessary. This involves separating the gold and silver using nitric acid. This step requires careful handling and proper safety precautions due to the corrosive nature of the acid. Refer to relevant safety data sheets (SDS) before attempting this step.

-

Final Purification: After the cupellation and parting (if required), the refined gold is left as a solidified button. This button may require further cleaning to remove any residual impurities.

<h3>Safety Precautions:</h3>

Kicker's fire refining is inherently dangerous. Working with molten metals and chemicals necessitates a high level of caution:

- Proper Ventilation: Ensure adequate ventilation to avoid inhaling harmful fumes.

- Protective Gear: Always wear appropriate protective equipment, including safety glasses, gloves, and a respirator.

- Fire Safety: Have a fire extinguisher readily available and be aware of potential fire hazards.

- Acid Handling: If parting is required, follow all necessary safety precautions when handling nitric acid. Consult the SDS.

- Proper Disposal: Dispose of waste materials responsibly and in accordance with local regulations.

<h3>Limitations of Kicker's Fire Refining:</h3>

While effective for smaller-scale operations, kicker's fire refining has limitations:

- Lower Purity: Compared to modern electrolytic refining, the final purity might be slightly lower.

- Labor Intensive: The process is more labor-intensive and time-consuming than industrial methods.

- Environmental Concerns: Improper disposal of waste materials can create environmental issues.

Kicker's fire refining offers a fascinating glimpse into traditional gold purification methods. While modern techniques offer higher purity and efficiency, understanding this historical process provides valuable insights into the history of metallurgy and the enduring human fascination with gold. Remember to prioritize safety above all else when attempting any form of metal refining. Always consult with experienced professionals and adhere to strict safety protocols.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Understanding The Kicker's Fire-Refining Process. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Call The Midwife Series 15 Begins Filming Prequel Details Revealed

May 08, 2025

Call The Midwife Series 15 Begins Filming Prequel Details Revealed

May 08, 2025 -

Unexpected Travel Snag Frontier Airlines Passenger Argues With Gate Agent

May 08, 2025

Unexpected Travel Snag Frontier Airlines Passenger Argues With Gate Agent

May 08, 2025 -

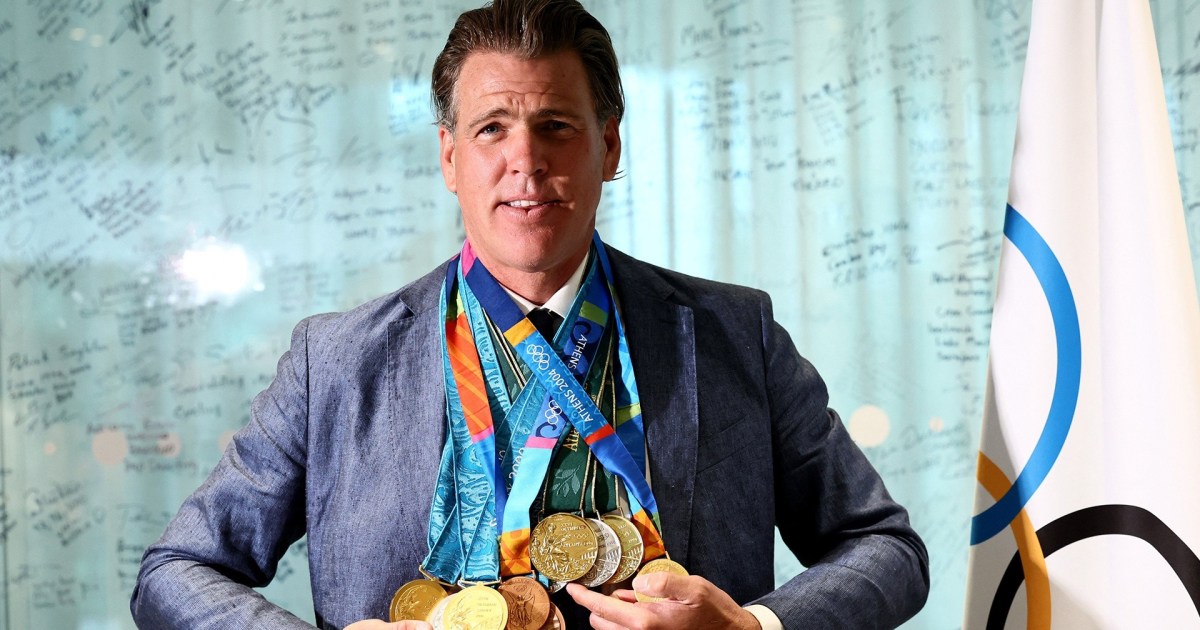

Olympic Legend Gary Hall Jr Gets Replacement Medals A Wildfire Story

May 08, 2025

Olympic Legend Gary Hall Jr Gets Replacement Medals A Wildfire Story

May 08, 2025 -

Passenger Disputes 25 Fee After Alleged Taunting By Frontier Airlines Staff

May 08, 2025

Passenger Disputes 25 Fee After Alleged Taunting By Frontier Airlines Staff

May 08, 2025 -

Cell Phone Evidence To Counter Karen Reads Defense In Murder Trial

May 08, 2025

Cell Phone Evidence To Counter Karen Reads Defense In Murder Trial

May 08, 2025