Understanding The Fire-Refining Process Of Kicker Manufacturing

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit Best Website now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Understanding the Fire-Refining Process in Kicker Manufacturing: A Deep Dive into Speaker Quality

Kicker, a name synonymous with high-performance audio, employs rigorous manufacturing processes to deliver exceptional sound quality. One crucial step often overlooked is fire-refining, a critical process impacting the final product's durability and performance. This article delves into the intricacies of fire-refining as it relates to Kicker speaker manufacturing, explaining its importance and impact on the listening experience.

What is Fire-Refining in the Context of Speaker Manufacturing?

While the term "fire-refining" might conjure images of ancient blacksmiths, its application in modern speaker manufacturing is surprisingly relevant. In the context of Kicker's production, fire-refining isn't about purifying raw materials in a literal sense. Instead, it refers to a series of high-temperature processes used to enhance the properties of specific components, primarily the speaker's voice coil and cone assembly.

These processes aim to achieve several key objectives:

- Increased Durability: High temperatures strengthen the materials, making them more resistant to wear and tear over time. This translates to longer-lasting speakers that can withstand the rigors of daily use, particularly in demanding environments like vehicles.

- Improved Heat Resistance: Speakers generate heat during operation. Fire-refining helps components better withstand this heat, preventing degradation and maintaining consistent performance even at high volumes.

- Enhanced Stiffness and Stability: The processes involved can increase the rigidity of the cone, improving its ability to accurately reproduce sound waves. This directly impacts the clarity and precision of the audio output.

- Optimized Impedance Matching: Specific heat treatments can fine-tune the impedance of the voice coil, ensuring optimal power transfer and efficiency.

The Process: A Closer Look

While Kicker doesn't publicly disclose the precise details of their fire-refining processes for proprietary reasons, we can infer some of the techniques employed based on industry best practices. These likely include:

- Controlled Annealing: This heat treatment process slowly heats and cools the components, relieving internal stresses and improving their overall structural integrity.

- High-Temperature Curing: Certain adhesives and coatings used in speaker construction require high temperatures to fully cure and bond, creating a stronger and more durable assembly.

- Vacuum Forming: In some cases, high temperatures are used in conjunction with vacuum forming techniques to shape components precisely, ensuring consistent performance across all units.

The Impact on Sound Quality

The benefits of fire-refining extend beyond simply increasing durability. By enhancing the physical properties of the speaker components, this process directly contributes to:

- Crisper Highs: A stiffer, more stable cone accurately reproduces high frequencies with greater detail and clarity.

- Powerful Bass Response: Enhanced durability and heat resistance allow the speaker to handle higher power levels without distortion, resulting in a more impactful bass response.

- Reduced Distortion: The improved stability and impedance matching minimize distortion, leading to a cleaner, more accurate sound reproduction.

- Longer Lifespan: Speakers that withstand heat and stress better will last significantly longer, offering a superior return on investment.

Kicker's Commitment to Quality

Kicker's dedication to utilizing fire-refining highlights their commitment to producing high-quality, long-lasting audio products. This meticulous attention to detail is a key reason why Kicker speakers are a favorite among audiophiles and car enthusiasts alike. Their commitment to advanced manufacturing techniques underscores their position as a leader in the automotive audio industry.

Conclusion:

Fire-refining is a crucial, though often unseen, element in the manufacturing process of Kicker speakers. This sophisticated technique plays a significant role in delivering the exceptional sound quality and durability that Kicker is known for. Understanding this process provides further insight into the commitment to excellence that lies at the heart of Kicker's success. Learn more about Kicker's product line and their innovative manufacturing techniques by visiting their official website [link to Kicker website].

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Understanding The Fire-Refining Process Of Kicker Manufacturing. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Inside Gaza The Reality Of Life Under Intensified Israeli Military Actions

May 08, 2025

Inside Gaza The Reality Of Life Under Intensified Israeli Military Actions

May 08, 2025 -

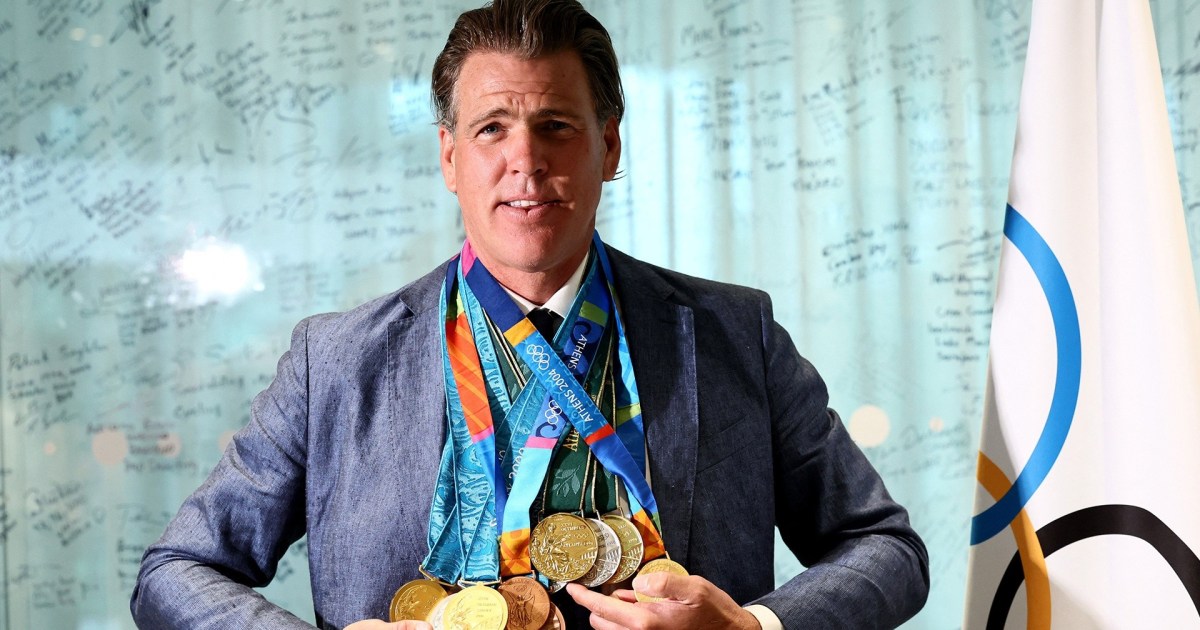

Wildfire Victims Gary Hall Jr Receives Replacement Olympic Medals

May 08, 2025

Wildfire Victims Gary Hall Jr Receives Replacement Olympic Medals

May 08, 2025 -

Thousands Of Preventable Deaths The Link Between Air Pollution And Emissions

May 08, 2025

Thousands Of Preventable Deaths The Link Between Air Pollution And Emissions

May 08, 2025 -

Live Score Pbks Vs Dc Ipl 2025 Rain Interrupts Play

May 08, 2025

Live Score Pbks Vs Dc Ipl 2025 Rain Interrupts Play

May 08, 2025 -

Watch Badosa Vs Osaka Rome Preview Live Streaming And Betting Tips

May 08, 2025

Watch Badosa Vs Osaka Rome Preview Live Streaming And Betting Tips

May 08, 2025