Understanding The Fire-Refinement Process Of Kickers

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit Best Website now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Understanding the Fire-Refinement Process of Kickers: A Deep Dive into Bootmaking

The iconic "Kickers" brand is synonymous with durable, stylish footwear. But what truly sets their boots apart? Beyond the trendy designs and comfortable fits lies a meticulous manufacturing process, and a key element is the often-overlooked fire-refinement process. This article delves into the details of this crucial step, explaining its impact on the quality and longevity of Kickers boots.

While Kickers doesn't publicly detail the exact specifics of their proprietary fire-refinement process – protecting their trade secrets – we can explore the general principles behind similar techniques used in leather bootmaking to understand its importance.

What is Fire-Refinement in Bootmaking?

Fire-refinement, also sometimes referred to as toasting or baking, is a process where leather is carefully exposed to heat. This isn't a haphazard burning; it's a precisely controlled procedure designed to achieve several key objectives:

- Enhanced Durability: Heat treatment helps to shrink and tighten the leather fibers, making the material more resistant to wear and tear. This results in boots that can withstand the rigors of daily use for a significantly longer period.

- Improved Water Resistance: The heat can help to close the pores in the leather, improving its natural water resistance. While this doesn't make Kickers boots completely waterproof (consider using a leather protector for optimal waterproofing), it enhances their ability to repel moisture.

- Enhanced Appearance: The fire-refinement process can subtly alter the leather's texture and color, giving it a richer, more nuanced look. This contributes to the distinctive aesthetic that Kickers boots are known for.

- Reduced Shrinkage: While the process does involve some shrinkage, the controlled heating helps to minimize post-production shrinkage, ensuring a more consistent final product.

The Specifics of Kickers' Process (Speculation & Industry Knowledge)

While Kickers keeps the details of their fire-refinement process confidential, we can infer certain aspects based on industry best practices. It's likely that their process involves:

- Precise Temperature Control: Maintaining the correct temperature is critical. Too much heat can damage the leather, while too little won't achieve the desired effects.

- Controlled Humidity: The humidity level during the heating process also plays a vital role in achieving the optimal balance of shrinkage, durability, and appearance.

- Specific Leather Selection: The type of leather used significantly impacts the effectiveness of the fire-refinement process. Kickers likely selects high-quality leathers specifically suited to withstand this treatment.

The Importance of Quality Control

The success of the fire-refinement process hinges on meticulous quality control. Throughout the entire process, skilled craftspeople monitor the leather's condition, ensuring it undergoes the precise treatment needed to achieve the desired outcome. This attention to detail contributes significantly to the superior quality of Kickers boots.

Beyond Fire-Refinement: The Full Picture of Kickers Quality

The fire-refinement process is just one piece of the puzzle. Kickers' commitment to quality extends to every stage of production, from the selection of raw materials to the final stitching. This dedication to craftsmanship ensures that each pair of Kickers boots is built to last.

For those seeking durable, stylish, and long-lasting boots, understanding the role of the fire-refinement process helps appreciate the meticulous care that goes into creating iconic Kickers footwear. While the precise details remain a guarded secret, the end result speaks for itself. Are you ready to experience the quality of a Kickers boot for yourself? [Link to a relevant Kickers retailer or website – optional].

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Understanding The Fire-Refinement Process Of Kickers. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Following The Testimony Livestream Of Karen Read Murder Retrial

May 08, 2025

Following The Testimony Livestream Of Karen Read Murder Retrial

May 08, 2025 -

A New Pope For A Changing World The Vaticans Crucial Conclave

May 08, 2025

A New Pope For A Changing World The Vaticans Crucial Conclave

May 08, 2025 -

Rdu Airport Viral Video Shows Heated Exchange Between Passenger And Frontier Agents

May 08, 2025

Rdu Airport Viral Video Shows Heated Exchange Between Passenger And Frontier Agents

May 08, 2025 -

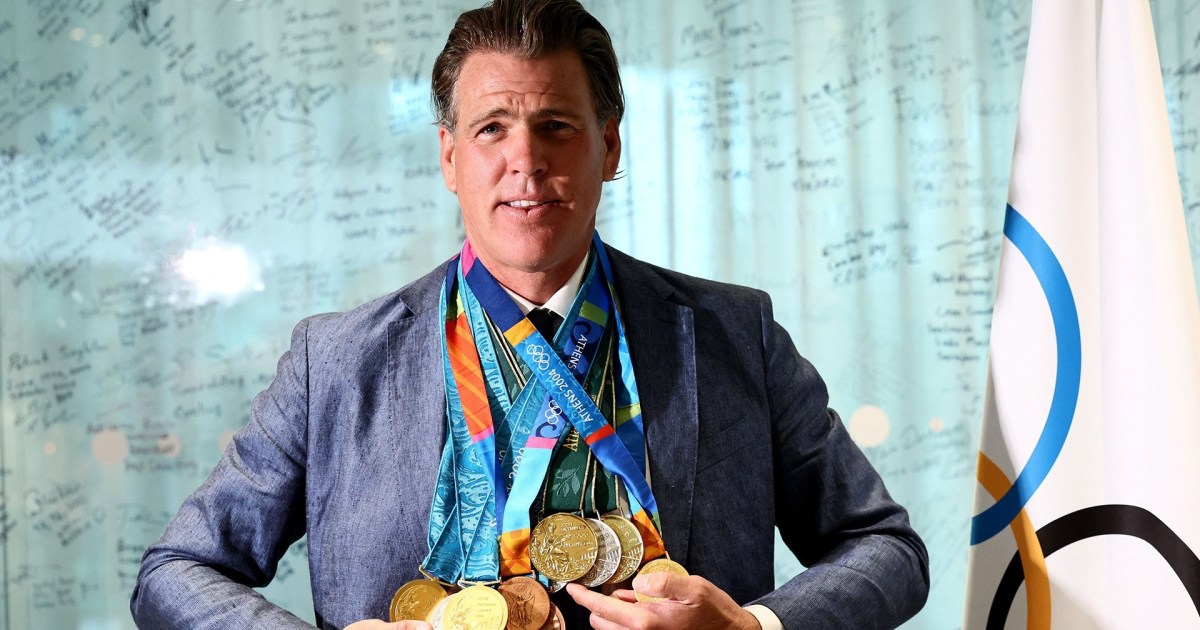

Olympic Legend Gary Hall Jr Gets Replacement Medals After Fire Loss

May 08, 2025

Olympic Legend Gary Hall Jr Gets Replacement Medals After Fire Loss

May 08, 2025 -

Investigation Launched After Indian Missile Strikes Pakistan

May 08, 2025

Investigation Launched After Indian Missile Strikes Pakistan

May 08, 2025