Kicker Technology: Refined Through Intense Heat Treatment

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit Best Website now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Kicker Technology: Refined Through Intense Heat Treatment

Revolutionizing Performance with Heat Treatment: A Deep Dive into Kicker's Advanced Manufacturing

For years, Kicker has been synonymous with high-performance audio. But what's the secret behind their superior sound quality and enduring durability? A significant part of the answer lies in their innovative use of intense heat treatment during the manufacturing process. This isn't just about making things stronger; it's about refining the very essence of the materials, pushing the boundaries of audio technology to deliver an unparalleled listening experience.

What is Heat Treatment in Kicker's Manufacturing Process?

Heat treatment is a crucial step in Kicker's manufacturing process, impacting the performance and longevity of their speakers, amplifiers, and subwoofers. This process involves carefully controlled heating and cooling cycles applied to specific components. The exact methods vary depending on the material and desired outcome, but the overarching goal is to alter the material's microstructure, improving its mechanical properties.

The Benefits of Intense Heat Treatment for Kicker Components:

-

Enhanced Strength and Durability: Heat treatment significantly increases the tensile strength and fatigue resistance of metals used in Kicker's products. This translates to speakers that can withstand the rigors of high-volume playback and remain durable over extended periods. This is particularly important for car audio systems that endure vibrations and temperature fluctuations.

-

Improved Hardness and Wear Resistance: The heat treatment process can increase the hardness of components, leading to greater wear resistance and a longer lifespan. This is crucial for moving parts within speakers and amplifiers, ensuring consistent performance over time.

-

Reduced Internal Stress: Manufacturing processes can introduce internal stresses into materials. Heat treatment helps relieve these stresses, improving the overall structural integrity and reducing the risk of component failure.

-

Optimized Magnetic Properties: In some Kicker components, like speakers with powerful magnets, heat treatment is used to optimize the magnetic properties, enhancing the efficiency and power output of the speaker system.

Beyond the Basics: Specific Applications in Kicker Products

Kicker doesn't simply apply a generic heat treatment process. Their engineers meticulously tailor the heat treatment parameters to suit the specific requirements of each component. For example:

-

Woofer Cones: The heat treatment process may focus on increasing the stiffness and damping properties of woofer cones, enhancing their ability to reproduce low frequencies accurately and efficiently.

-

Tweeter Domes: Heat treatment can improve the rigidity and precision of tweeter domes, resulting in clearer, more detailed high-frequency response.

-

Amplifier Components: For amplifier components, heat treatment might be used to enhance the thermal conductivity and stability, improving the amplifier's efficiency and reliability.

The Future of Heat Treatment in Kicker Technology:

As materials science advances, Kicker is likely to continue refining its heat treatment processes. This ongoing innovation will undoubtedly lead to even greater improvements in the performance, durability, and longevity of their products. Their commitment to this meticulous approach underscores their dedication to providing consumers with the highest-quality audio experience.

Conclusion:

Kicker's commitment to precision heat treatment is a testament to their dedication to quality and performance. This advanced manufacturing technique isn't just a detail; it's a fundamental element that sets Kicker apart, delivering audio systems that are both powerful and remarkably long-lasting. Learn more about Kicker's innovative approach to audio technology by visiting their website [link to Kicker website]. Understanding the science behind the sound elevates the listening experience.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Kicker Technology: Refined Through Intense Heat Treatment. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

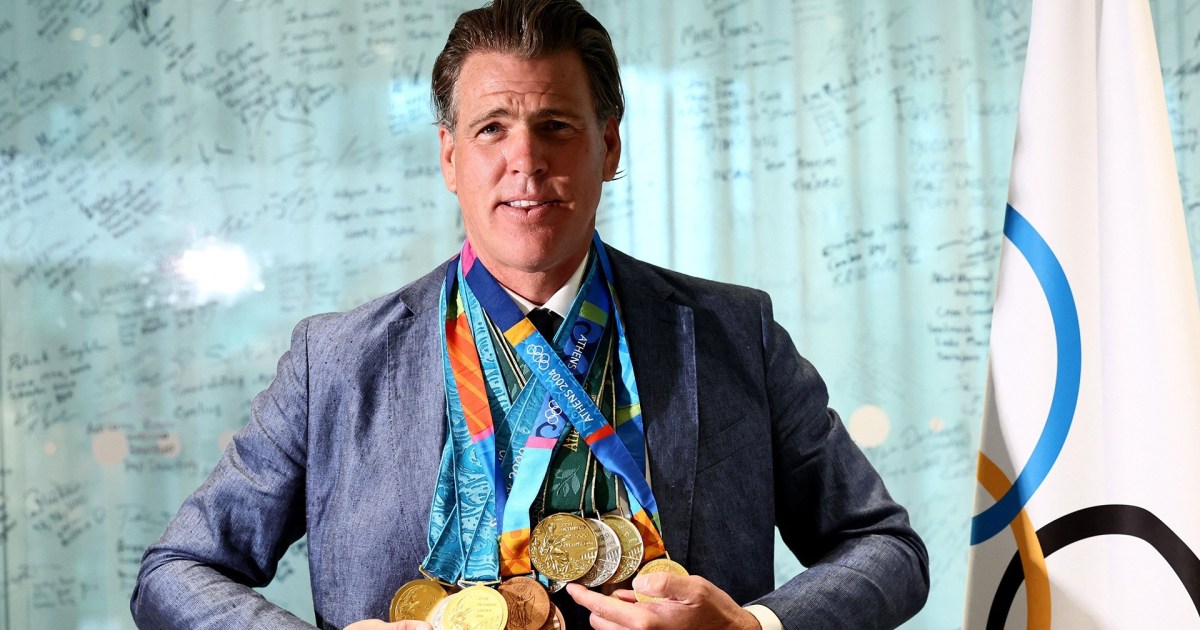

Wildfires Prompt Replacement Olympic Medals For Gary Hall Jr

May 08, 2025

Wildfires Prompt Replacement Olympic Medals For Gary Hall Jr

May 08, 2025 -

May 7 2025 Catch The Preston And Steve Show Live Stream

May 08, 2025

May 7 2025 Catch The Preston And Steve Show Live Stream

May 08, 2025 -

Rome Masters Osaka Progresses Swiatek And Fonseca Headline Tennis Tracker

May 08, 2025

Rome Masters Osaka Progresses Swiatek And Fonseca Headline Tennis Tracker

May 08, 2025 -

Catch The Preston And Steve Show Livestream May 7 2025

May 08, 2025

Catch The Preston And Steve Show Livestream May 7 2025

May 08, 2025 -

Will Brazils Renewable Energy Drive Its Ai Revolution

May 08, 2025

Will Brazils Renewable Energy Drive Its Ai Revolution

May 08, 2025